Technical

Information--Tran-Oxide Pigments

Careful control of the preparation

process for Trans-oxide pigments results in the

formation of pigments with very small primary

particle sizes.

The particles are

acicular with needle lengths of up to 43nm and

needle widths up to 9nm . Typical specific

surface is 105

-150m2/g , and hence, for inorganic

pigment , have relatively high oil absorption

figure. All of the Trans-oxide pigment range

exhibit high levels of transparency and color

strength combined with excellent chemical

stability, acid-resistance, and

alkaline-resistance , as inorganic pigment, they

are non-bleeding,non-migratory and are not

soluble allowing good effects to be achieved in

both water and oil based systems.

Trans-oxide

pigment have good stability to temperature , the

red can suffer up to

300

°C, and yellow, black , green , and brown up to

be

160°C.

Trans-oxides are strong

absorbers of ultraviolet radiation . The higher

the degree of dispersion to expose the maximum

surface area of the pigments , not only improve

the transparency of the paint film , but also

allows for a high level of absorption of the

damaging UV light.

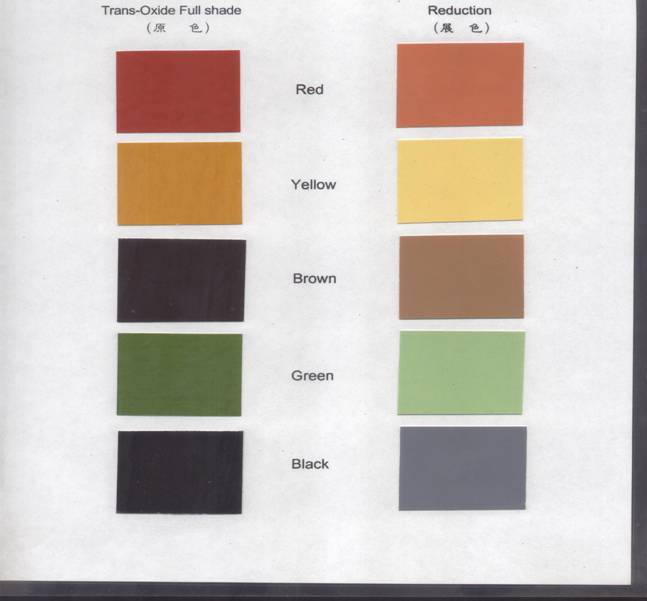

The color shade nuances of

Trans-oxide pigments can be obtained by

changing the manufacturing process to influence

particle shape with high surface areas.So we can

offer Trans-oxide pigments with subtle nuances

of color shade.

According to the X-ray

analysis to our pigments , the contents of Pb ,

Sn , Cd are under 100ppm , which meet the EN71

(1994) Part 3 specification and proves our

products are high quality environmentally

acceptable

materials.

Applications Trans-oxide pigments are mostly used in

automotive paints and wood finishes. Meanwhile

they are also widely used in the areas of

construction paints, industrial coatings ,

plastic , nylon , rubber,print ink, art

coatings, cosmetics and powder coatings.

The

excellent weather fastness, UV absorption

properties,high transparency and color strength

makes Trans-oxide to enrich the colors ,

increase color shades when combined with organic

pigments and dyes and improve the condition of

poor weather fastness when organic pigments and

dyes are used alone without Trans-oxide

pigments.

Automotive

Paints Trans-oxide pigments give the

stylist the ability to improve durability ,

transparency and UV absorption of the paint. So

they are widely used in automotive paints and in

conjunction with aluminum and pearlescence to

produce metallic and golden yellow finishes. At

the same time , significant cost benefits by

allowing cost effective color stylings in

combination with more expensive organic pigments

can be achieved.

Transparent yellow iron

oxide is used in combination with phthalo

cyanine pigments to achieve gold to green

shades, while transparent red and brown iron

oxides can be combined to blue shade reds and

maroons.

Wood Coatings The ultraviolet component of sunlight is

principally responsible for the degradation of

wood. Trans-oxide pigments are strong absorbers

of UV radiation providing protection for the

wood while their color and transparency enhances

the appearance of the natural wood grain with a

soft color. The high durability and weather

fastness of Trans-oxide pigments make them the

natural choice for wood stains and furniture

finishes.

Plastic

Application There is a growing

requirement for the use of Trans-oxide in

plastic application .Owing to its properties of

high transparency and color strength and strong

absorption of UV, for example , when we use them

as the coloring matter of transparent plastic

containers , they can also work as UV radiation

absorber which can protect the goods in the

containers from UV radiation.They can be applied

in PET or PP for drinking cans and medicine

bottles.

Industry Coating Coatings containing Trans-oxide

pigments can produce attractive gold and copper

effects when applied over metal.

Trans-oxide

pigments are suitable for cosmetics and both

exterior and interior coating system and

children toys.

Print

ink The transparent iron oxide is as

bright as similar organic pigments and

transparent dyestuffs, which is suitable for

printing of aluminum tube. Due to successful

application of car coatings, it may be used in

preparation of metallic paints.

Art coatings Art

coatings including metallic paints (water or oil

dispersion), scaly figure paint and hammer

paint, may keep the art colors for long period

due to the high durability property of

transparent iron

oxide.

Cosmetics Because

transparent iron oxide is non-toxic and has a

high UV ray absorption, it is applicable in

cosmetic industry (water dispersion).

Powder coating Transparent iron oxide is able to keep colors

unchanged in 5-20 minutes under 130

-200 ℃, so it may be used in powder

coating.

Methods of

Application In order to fully exhibit

the high transparency and color strength, the

Trans-oxide pigments must be dispersed

completely. The forces of attraction between

particles of small size are high and aggregates

formed between the particles are difficult to

fully disperse . Ideal dispersion depends on the

manufacturing process and the

equipment.

The first stage of a

dispersion is to choose proper dispersants and

solvent to wet the pigment surface to make it to

be predispersion system and then choose proper

equipment.

For relatively low viscosity

systems, a bead mill containing glass, steel or

zirconia media is preferred , although ball

mills or attritors may also be used . Where

viscous systems are required ,for example pastes

or concentrates at high pigment loading ,then a

triple roll mill may be required.

After

full dispersion , with the needle lengths of the

particles under 5μm, the excellent properties of

Trans-oxide pigments will be fully exhibited.

We can supply fully dispersed

pigment dispersions in both water-based and

solvent-based systems.

Transparent Iron Oxide Pigments

| Items |

Solvent-Borne |

Water-Borne |

| Trans-oxide Yellow |

TY-608-2R TY-608-3 TY-618 |

TY-618 |

| Trans-oxide Red |

TR-708-4R TR-708-5 TR-718 |

TR-718 |

| Trans-oxide Green |

TG-808 |

TG-808W |

| Trans-oxide Black |

TB-908 |

TB-908W |

| Trans-oxide Brown |

TB-1008R |

TB-1008RW |

Transparent

Iron Oxide Pigments Dispersions

| Items |

Solvent-Borne |

Water-Borne |

| Trans-oxide Yellow Dispersions |

SP 608 |

SP 608W |

| Trans-oxide Red Dispersions |

SP 708 |

SP 708W |

| Trans-oxide Green Dispersions |

SP 808 |

SP 808W |

| Trans-oxide Black Dispersions |

SP 908R |

SP 908RW |

| Trans-oxide Brown Dispersions |

SP 1008R |

SP

1008RW |

Technique

standards of solvent Borne Nano-grade

Trans-Oxide pigment

| Items |

TY-608-2R |

TY-608-3

TY-618 |

TR-708-4R |

TR-708-5

TR-718 |

TG-808 |

TB-908 |

TB-1008R |

| Appearance |

yellow powder |

yellow powder |

red powder |

red powder |

Green powder |

Black powder |

Brown powder |

| Color(compared with the standard) |

Similar |

Similar |

Similar |

Similar |

Similar |

Similar |

Similar |

| Relative coloring powder( Compared with the

standard) % |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

| Volatile matter at

105°C |

≤3.5 |

≤3.5 |

≤3.5 |

≤3.5 |

≤3.5 |

≤3.5 |

≤3.5 |

| Water soluble matter % |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

| Residue on 45μm mesh % |

≤0.1 |

≤0.1

≤0.05 |

≤0.1 |

≤0.1

≤0.05 |

≤0.05 |

≤0.1 |

≤0.1 |

| PH of water suspension |

4-6 |

4-6

7-9 |

4-6 |

4-6

7-9 |

4-6 |

7-8 |

4-6 |

| Oil absorption g/

100g |

30-35 |

35-40

30-35 |

30-35 |

35-40

30-35 |

30-40 |

25-30 |

30-35 |

| Total iron-oxide % |

≥82.0 |

≥80.0 |

≥92.0 |

≥90.0 |

≥82.0 |

≥93.0 |

≥82.0 |

| Oil resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Water resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Alkaline resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Acid resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Solvent resistance (alcohol resistance

methylbenzene resistance) |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| UV absorption |

≥95% |

≥95% |

≥95% |

≥95% |

≥85% |

≥85% |

≥85% |

Technique

standards of Water Borne Nano-grade Trans-Oxide

pigment

| Items |

TY-618 |

TR-718 |

TG-808W |

TB-908W |

TB-1008RW |

| Appearance |

yellow powder |

red powder |

Green powder |

Black powder |

Brown powder |

| Color(compared with the standard) |

Similar |

Similar |

Similar |

Similar |

Similar |

| Relative coloring powder( Compared with the

standard) % |

≥98 |

≥98 |

≥98 |

≥98 |

≥98 |

| Volatile matter at

105°C |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

| Water soluble matter % |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

| Residue on 45¦Ìm mesh % |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

| PH of water suspension |

7-9 |

7-9 |

7-9 |

7-9 |

7-9 |

| Oil absorption g/

100g |

30-35 |

30-35 |

30-40 |

25-30 |

30-35 |

| Total iron-oxide % |

≥82.0 |

≥90.0 |

≥82.0 |

≥93.0 |

≥90.0 |

| Oil resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Water resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Alkaline resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Acid resistance |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| Solvent resistance (alcohol resistance

methylbenzene resistance) |

5 grade |

5 grade |

5 grade |

5 grade |

5 grade |

| UV absorption |

≥95% |

≥95% |

≥85% |

≥85% |

≥85% |

Technique

standards of Solvent Borne Nano-grade

Trans-Oxide pigment

| Items |

SP 608 |

SP 708 |

SP 808 |

SP 908 |

SP908R |

SP1008R |

SP2008 |

| pigment content |

50% |

50% |

50% |

50% |

20% |

50% |

30% |

| Binder content |

34% |

34% |

44% |

25% |

16% |

25% |

16% |

| Solvent content |

16% |

16% |

6% |

25% |

64% |

25% |

54% |

| Particle size<<> |

5μm |

5μm |

5μm |

5μm |

5μm |

5μm |

5μm |

| Density |

1.3g/cm3 |

1.3g/cm3 |

1.1g/cm3 |

1.3g/cm3 |

1.1g/cm3 |

1.3g/cm3 |

1.1g/cm3 |

Technique

standards of Water Borne Nano-grade Trans-Oxide

pigment dispersions

| Items |

SP 608W |

SP 708W |

SP 808W |

SP 908W |

SP908RW |

SP 1008RW |

SP2008W |

| pigment content |

40% |

40% |

40% |

40% |

20% |

40% |

30% |

| Binder content |

15% |

15% |

15% |

10% |

24% |

12% |

14% |

| Solvent content<H2O> |

45% |

45% |

45% |

50% |

56% |

48% |

56% |

| Density |

1.4g/cm3 |

1.4g/cm3 |

1.4g/cm3 |

1.4g/cm3 |

1.3g/cm3 |

1.4g/cm3 |

1.4g/cm3 |

| PH value |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

| Particle size<<> |

5μm |

5μm |

5μm |

5μm |

5μm |

5μm |

5μm |

|